How much refrigerant does your air conditioner hold?

How do we know when it’s properly charged?

How do we know when it’s low?

What if my system has too much?

These are all good questions. And if you ask someone that does HVAC service, you will likely get a different answer from each one. So what’s correct? How do you know who to trust? Let’s start with the 3 questions above and take care of them individually.

How much refrigerant does your air conditioner hold?

This is a very difficult question to answer. It depends on the size (capacity), equipment selection, refrigerant type, and length of refrigerant piping. Typical residential systems hold between 5 and 20 pounds of refrigerant. On average it’s about 3 pounds per ton (12,000 BTU) of air conditioning.

For a brand new system, it’s very easy for us. Our equipment is matched so we know how much the air conditioner and evaporator coil hold. The only variable is the refrigerant piping. Most equipment comes pre-charged with enough refrigerant for the equipment and a few feet of refrigerant piping. All we have to do is calculate what’s needed by using the pipe diameter and additional length not accounted for from the factory. It is “weigh” it in by using scales.

How do we know when it’s properly charged?

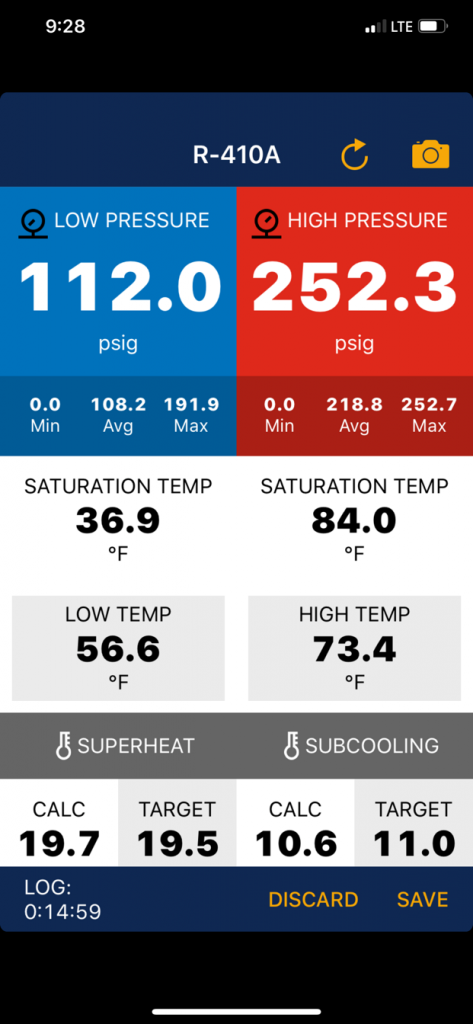

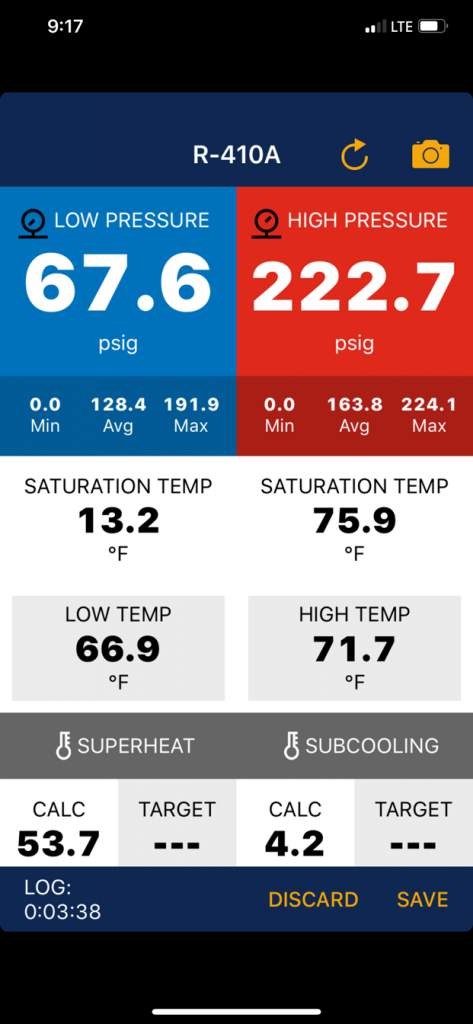

As mentioned above, on a new system we weigh in the proper amount. But what about if some leaks out? There are a couple of ways. Factory charging charts or superheat/subcool. Factory charging charts are typically not readily available so the latter is the most common method. Before we can determine a proper charge, we have to determine what the proper superheat and subcooling are. This is done by measuring the outdoor temperature and the indoor wet bulb. Indoor wet bulb is determined by using a device called a sling psychrometer or calculated using the temperature, humidity and atmospheric pressure. At that point we are able to use a standard chart or software to determine the proper superheat and subcooling for the air conditioner at those operating conditions. Those values do change as the temperatures and humidity changes.

The temperature of refrigerant always corresponds to it’s pressure. We use charts to convert the pressure to temperature. Superheat is the difference between the suction line (large copper line) temperature and the temperature of the refrigerant on the low side of the system. Subcooling is the difference between the refrigerant temperature on the condenser side of the system and the liquid line (small copper line).

Superheat basically tells us about the refrigerant on the evaporator side of the system and subcooling the condenser side. If superheat is high, there isn’t enough refrigerant in the evaporator coil. If it’s low, there is too much. It’s the opposite for subcooling. Low means there isn’t enough in the condenser and high means there is too much. Keep in mind, that other things can have an effect on these other than the actual amount of refrigerant in the system.

How Do We Know If It’s Low?

High superheat and low subcooling combined with lower than expected pressures will indicate a low system charge. There are combinations of other problems that can simulate these conditions, but we must have somewhere to start. If a system appears low, we add refrigerant until we achieve the desired superheat and subcooling without raising the pressures beyond normal. Why is not having enough bad? Cooling performance is the biggest reason, but it can also lead to compressor failure. Compressors are cooled by the refrigerant coming back. If the superheat is too high, the compressor can fail due to over heating.

What If My System Has Too Much?

If we see a low superheat and a high subcooling combined with higher than expected pressures, we may need to remove some refrigerant. We do this by simply pumping some into a recovery bottle with the system running. Why is too much bad? Many reasons. Too much refrigerant can cause some very serious problems. No cooling, high electric bills and even damage to your compressor. Compressors are not designed to pump liquid and if liquid floods back to the compressor it can cause failure.

Simple?

Not exactly. There are hundreds of things that can have an effect on system superheat and subcooling. This includes but is not limited to dirty evaporator coil, dirty condenser coil, dirty filter, duct issues, and even electrical components.

Who Do You Trust?

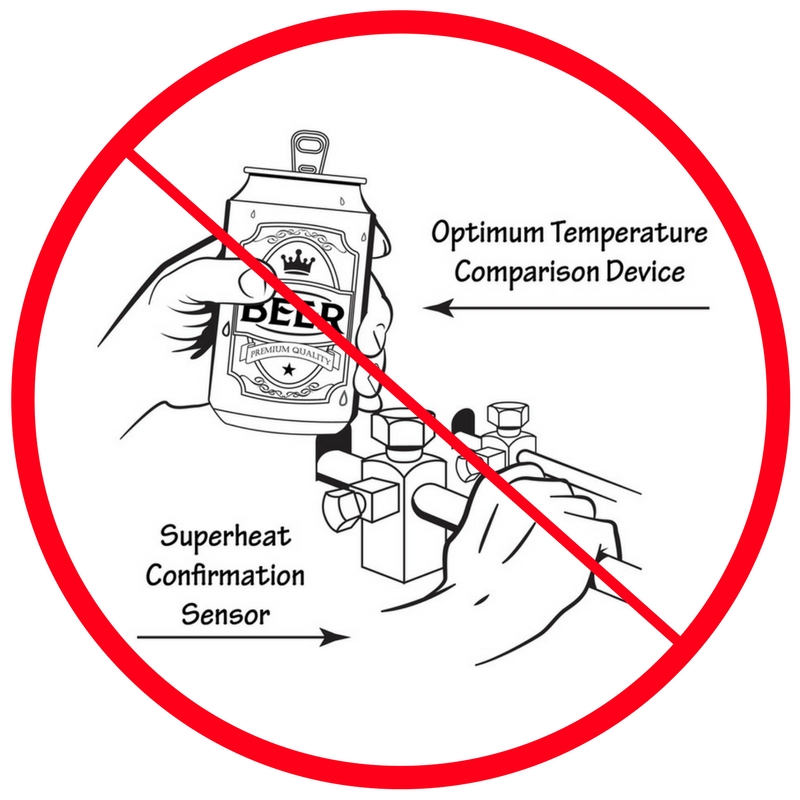

It’s fairly simple. If they use the proper tools and have an understanding of proper methods, it’s fairly safe to say that you can trust them. Things to watch out for are comments such as the following:

“The suction line should be Beer Can Cold”

“The suction line should be cool”

“It’s charged when it starts cooling”

Anyone working on HVAC equipment should have proper tools. And know proper procedures.

If your looking for someone you can trust, call NWA Cooling & Heating. We provide high quality service at a reasonable price. Our Google reviews speak for themselves.

(479) 936-1455

Author

Tom Calhoun